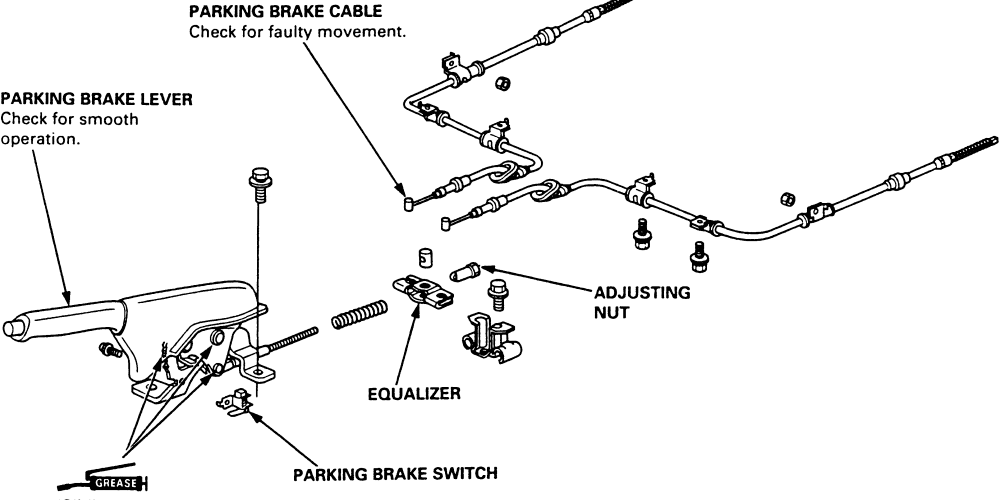

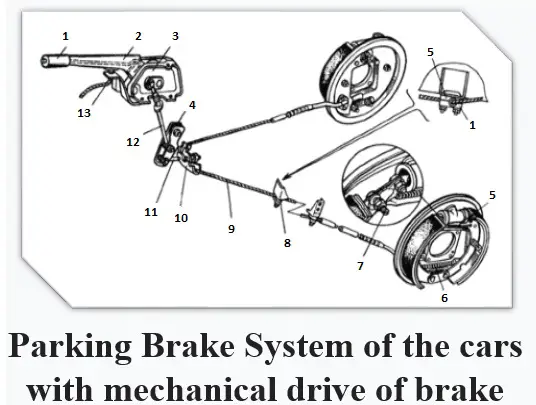

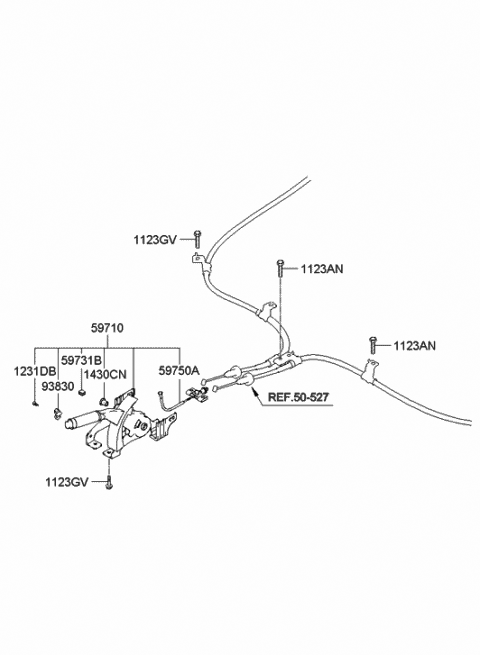

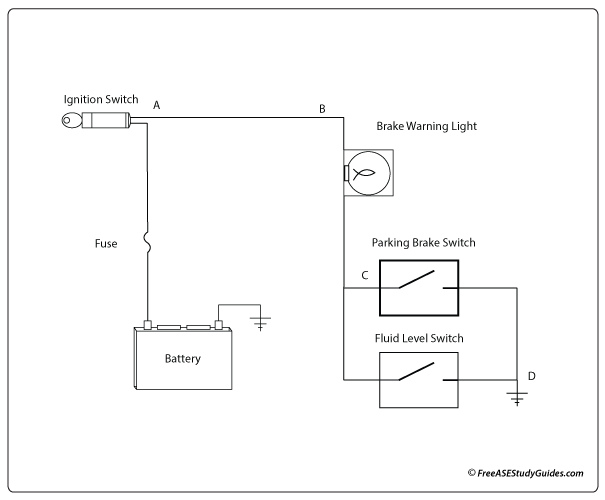

Parking Brake System Diagram

Parking brake system diagram. The trailer brake system has its own lines for operation and is used when there is a. COMPONENTS WORKING PRINCIPLE AND TYPES 3. Leaky defective brake valve.

As new components are introduced and their function explained they gradually build up to a complete functioning air brake system. Parking Brake System - Cable Operated Rear Brakes wHand Control. Brake Systems and Related Components.

The control line pressure required for the exhaust valve to close and the inlet valve to open and air to begin to flow from the delivery port. A drop in pressure of this circuit results in engaging of parking brakes. The perfect universal emergency brake kit and winner of the 2012 NSRA new safety product of the year.

1 Drive the vehicle at about 35 kmh 22 MPH. Build air pressure to governor cut-out pressure Check to see if valve is leaking air from the exhaust port. No air pressure in brake system.

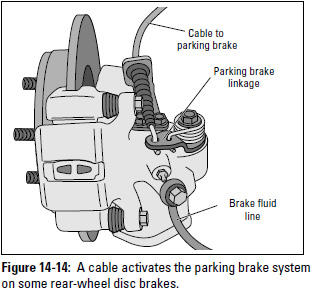

The BMW tool kit does supply the tool needed to manually release the Electronic Parking Brake if it will move they are usually seized solid and the owners manual explains how to perform a manual release. The brakes act on the rear wheels via a mechanism integrated with the rear brake callipers. On the assumption the tractor air brake system is functioning properly.

Trailer spring brake valve 19. Trailer brakes an every axle over the towing vehicles GVW. Identify the source of cause and rectify it.

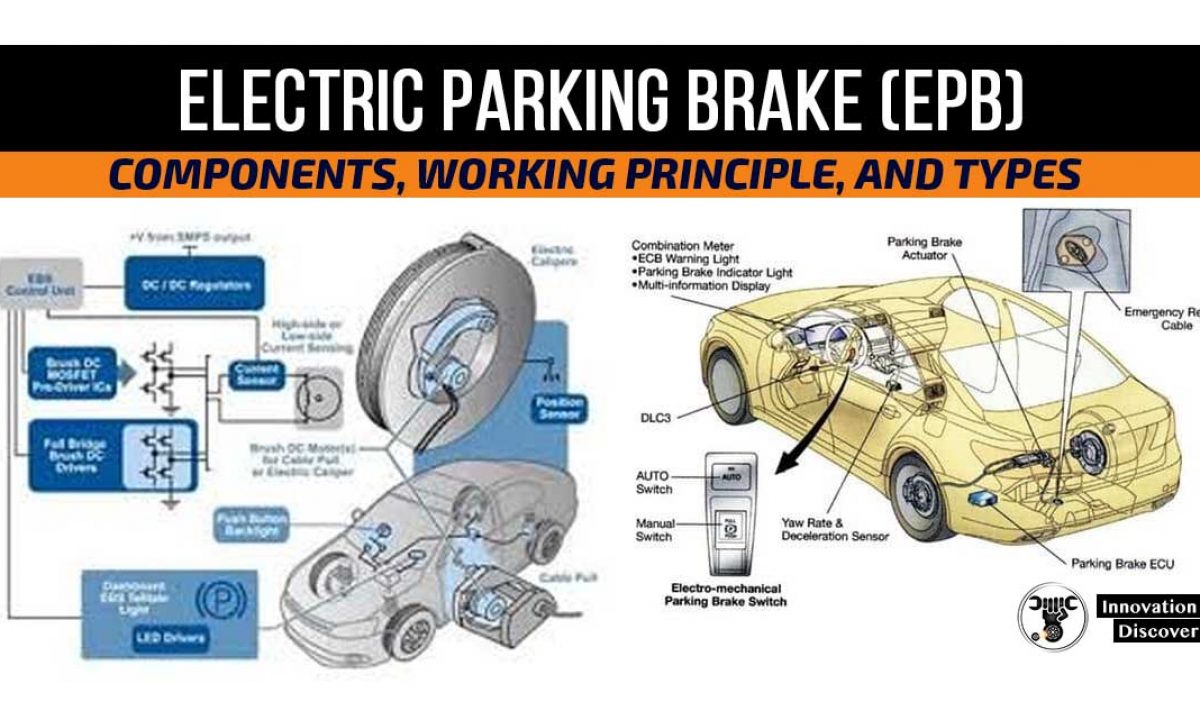

The electromechanical parking brake in comparison Conventional handbrake Electromechanical parking brake Operation Pull up handbrake lever Press electromechanical parking brake button Releasing Release handbrake lever Press electromechanical parking brake button Hillstart Complicated balance between handbrake accelerator and clutch pedal. 1967 F250 4x2 with HD Brakes F250 4x4.

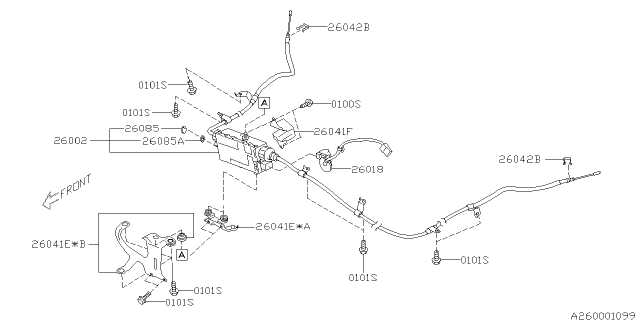

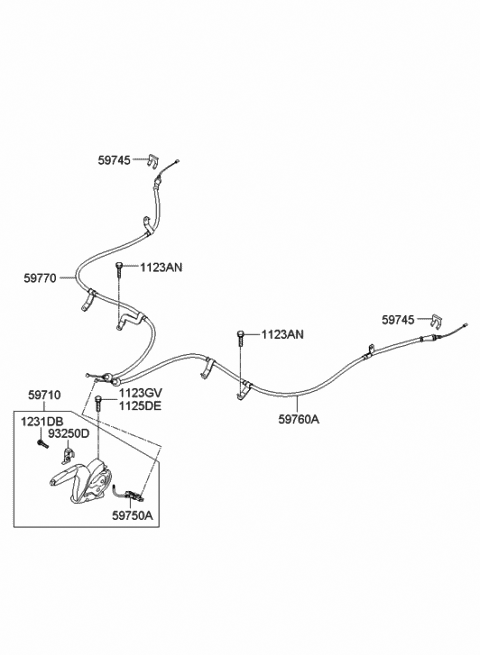

Technical Drawings and Schematics - Section B.

Parking break circuit is connected to a spring mechanism in which the air pressure is used to keep the spring in unlocked position. On the assumption the tractor air brake system is functioning properly. Car Brake System Diagram In this image you will find power booster master cylinder ABS caliper assembly ABS hydraulic unit hydraulic fluid lines brake pedal rotor in it. How Master Cylinders and Combination Valves Work. 1967 F250 4x2 with HD Brakes F250 4x4. The brake warning light operates as specified above. You may also find ABS system wiring drum parking brake cable electronic ABS controller car brake system brake system of car car car internal structure in this image. There are TONS more things that goes wrong with these POS parking brake systems but those three are the most common. 2 INSPECT PARKING BRAKE.

Components are introduced and shown with typical system diagrams to show where they are used. Restricted or broken pipe or hose. A key component is the parking brake latch. 1 Drive the vehicle at about 35 kmh 22 MPH. COMPONENTS WORKING PRINCIPLE AND TYPES 3. On the assumption the tractor air brake system is functioning properly. Trailer service brake chamber 15.

-brakes%2C-hand-brake-car.png)

Post a Comment for "Parking Brake System Diagram"